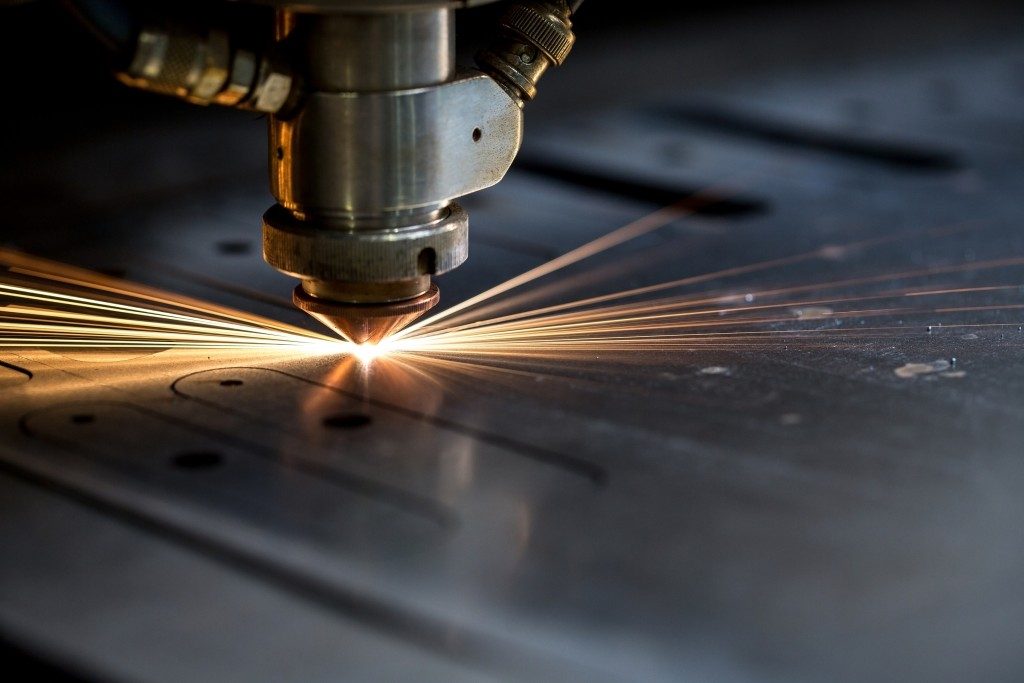

The introduction of laser technology in a lot of industries has dramatically improved manufacturing standards and processes. Such is the case in laser etching on stainless steel, engraving on heavy materials like granite, wood, and tombstones, or cutting different hardened materials.

In fact, here are some of the big benefits of using laser technology in aerospace, automotive, and other industries:

Non-Contact Method

Through the process of oxidation and coloration, laser beams can leave permanent marks onto a material without any physical contact. Any areas not targeted by laser beam retain its physical characteristics. This is essential especially in the engraving process in which the risk of damage to nearby parts is greater. By using a laser beam, only the targeted sections are removed.

High-Quality Precision Marking

Laser beams are applied precisely even by the smallest measurement, allowing high-quality, precise marks. And unlike traditional marking which can easily fade when subjected to changing temperature, laser marks are long-lasting. The reason is simple: laser beams do not only leave a mark, but they also completely alter a part of the material, making it harder to remove the marking.

Works on Different Materials

One of the good things about using a laser machine for engraving, marking, and etching among other methods is that it works on different kinds and forms of materials. Whether you’re working on ceramics, porcelains, or plastics, you won’t need to worry about failing to leave a mark on the material.

Works on Various Shapes and Sizes

Since laser technology works on different materials, it can also work on various shapes and sizes. You can use it on big or small, plain or complex, wide or rugged – any shape and size you can think of. From small forms like bottle caps, microchips, and motherboard parts to big pieces of an aircraft, laser marking can be used in many applications.

Environment-friendly

If you want to have sustainable etching or marking processes in your company whether for economic or environmental reasons, switching to laser technology is a good move.

Unlike traditional markers, laser machines use beams to discolor a material. They don’t use inks or chemicals, which can be harmful to the environment. They do not come with any ink cartridges, plastics wrappers, or tiny carton boxes. By producing precise marks, laser machines also produce less waste than conventional marking machines. Further, since it is efficient, laser technology uses less energy to produce.

Indeed, the use of the laser machine has brought vast improvements to many businesses and industries – aerospace, automotive, medical, electronics, and hundreds of manufacturing sectors.

Businesses that decided to upgrade from the traditional process into using laser machines are now reaping the benefits of a much modern approach. Laser technology hasn’t only made processes become more environment-friendly, but it has also cut the production time drastically. Faster production and higher quality products mean bigger savings and earning potentials for companies across the country.