We are living in an age of consumerism. Whether you like it or not, we do things daily that contribute to the creation of industrial waste. Practically everything we use on a daily basis, from eating at your local restaurant to buying new tires, is part of a process that creates industrial waste.

But thankfully, consumers are becoming more aware of the environmental impact that this waste causes. And companies are starting to listen as more of these consumers are choosing to vote with their money. This has caused both large and small-scale businesses to become more stringent with their industrial waste management. In Australia, where people value green solutions, many examples of proper management are cropping up.

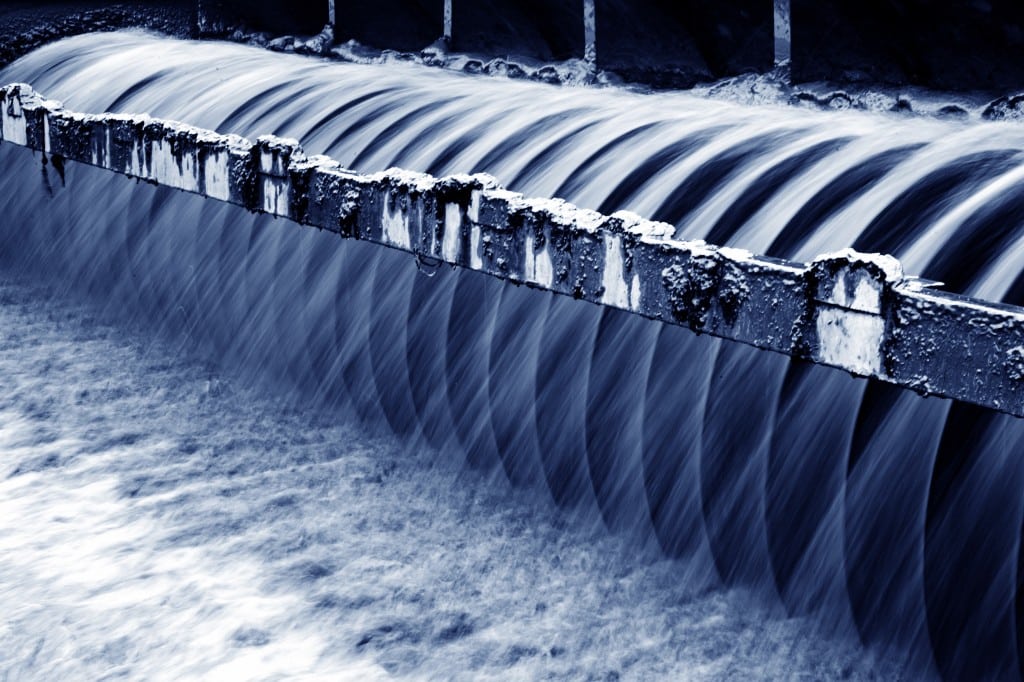

Industrial Wastewater

This type of waste is one of the most unsettling for many, as it can go directly back into bodies of water. Luckily, industrial wastewater management solutions in Australia are among the most advanced. With wastewater coming from such a varied number of industries such as paper and nuclear facilities, the need for proper waste management is big. Among the more common solutions is the filtration of wastewater to remove solids, oil, grease, or biodegradable organic materials.

The process behind industrial wastewater treatment varies depending on the foreign matter to be removed or the level of filtration it must undergo. But generally speaking, companies that specialize in this treatment use a variety of machines that use ions, osmosis, and other mechanical techniques.

Solid and Air-Borne Waste Disposal

The two other types of industrial waste are solid and gaseous. These are still heavily prominent but are likewise being managed to reduce the ecological effects. First, solid waste is commonly created at many factories and was previously disposed of via landfills. The effects of this on the environment, though, have caused an uptick in sorting sites. In these facilities, solid waste is sorted via a system of manpower and machines for proper disposal. This lessens the overall volume of waste to be disposed of.

Air-borne waste is a little trickier to sort out. But the first step is to identify the type of air contamination that a site may produce. From there, solution-providers can create a plan to reduce the contamination, figure out how best to contain it, and then create a process of removal with treatment.

For both solid and air-borne waste, a continuous set of filters and technologies working simultaneously ensures that all operations and management work in harmony.

Partnering Up to Reduce, Reuse, and Recycle

Of course, another rising option to treat industrial waste is to practice the 3 Rs. Many facilities that produce waste work with other plants and agree on a mutually beneficial practice. As it happens, one plants’ waste may be another’s raw material.

For example, vegetable scraps from a restaurant can be passed over to a hog farm or back to a vegetable farm for their food or fertilizer. Waste acid from one industry can also be used in another for processing.

A better understanding of industrial waste and how it can be managed is important for consumers to know what companies are doing and how things can be improved. Waste management solutions don’t necessarily mean zero-waste, but it certainly makes an impact on environmental conservation efforts.